02

automatic systems for

painting, spraying, gluing

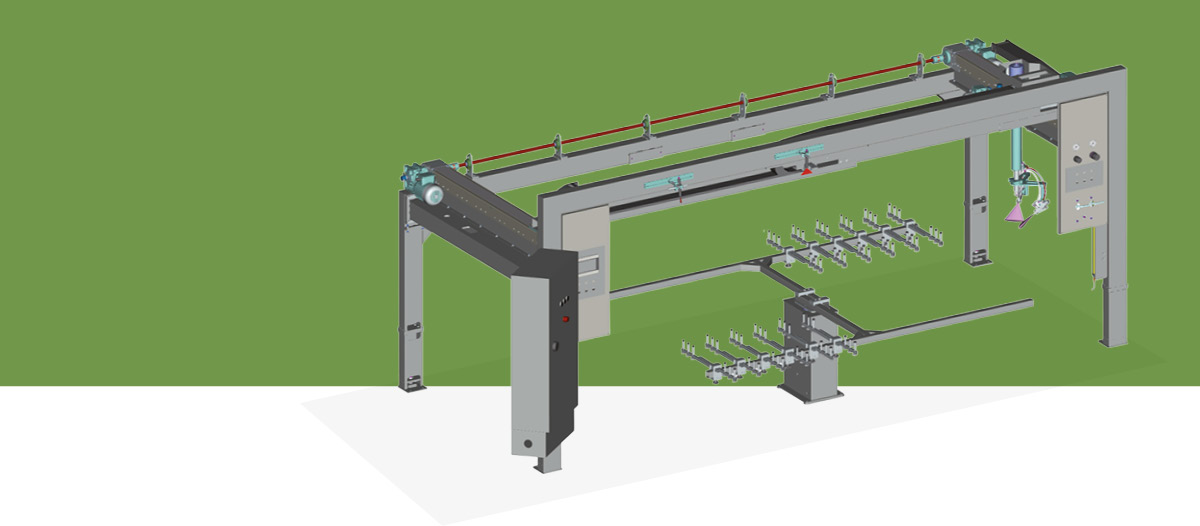

ROVER CAB

Painting system

Rover Cab is an automatic spraying robot, with a travelling arm with two controlled axes, for applying paints, glues, hues and liquid products in general on full or slotted objects and panels, with automatic spray guns; the standard machine is provided with a rotating supporting frame for panels.

Operation

The machine works with previously set programs, or by programming directly the spraying size; this function allows to optimise spraying, more precisely:

– cutback paint, compared to manual spraying, thanks to the overspray control;

– reduced obstruction of the filtering systems and a subsequent improved respect for the environment;

– constant application quality for all types of utilisation.

The rotating supporting frame for panels allows to easily and safely handle the panels during loading and unloading, by the operator, when the robot is working.

The machine is able to spray with a cross movement, for a higher application quality, both when spraying on flat surfaces and on edges.

Utilisation

Rover Cab was designed to be used on small and average productions, and in general whenever it is possible and necessary to replace the operator in the manual spraying operation.

It is particularly fit for spraying panels, wooden doors and fancy goods, glass, plastics etc., especially when a high and constant application quality is required; the machine can be personalised and supplied with spraying equipment and panel supporting systems for any requirement.

Plus

- Moderate investment against high productivity

- Machine applicable to existing spray booths

- The machine does not preclude the manual utilisation of the spray booth

- Very little preparation and cleaning operations

- Easy and user-friendly, also for small quantities of parts